language

Peritoneal Dialysis Solution (CAPD) Production Line

Optimal peritoneal dialysis solutions: safe, sterile, and efficient care

Email: iven@pharmatechcn.com

Tel: +86 21 58716151

Our Peritoneal Dialysis Solution Production line is used for CAPD solution or irrigation bag printing, forming, filling and sealing. Bag size ranges from 2000ml to 5000ml. It has features of compact structure, small space occupation, and various data can be adjusted and save for welding, printing, filling, CIP & SIP like temperature, time, pressure, as well can be printed out as required. The main drive combined by servo motor with synchronous belt, accurate position. Advanced mass flow meter gives precise filling, volume can be adjusted easily by HMI.

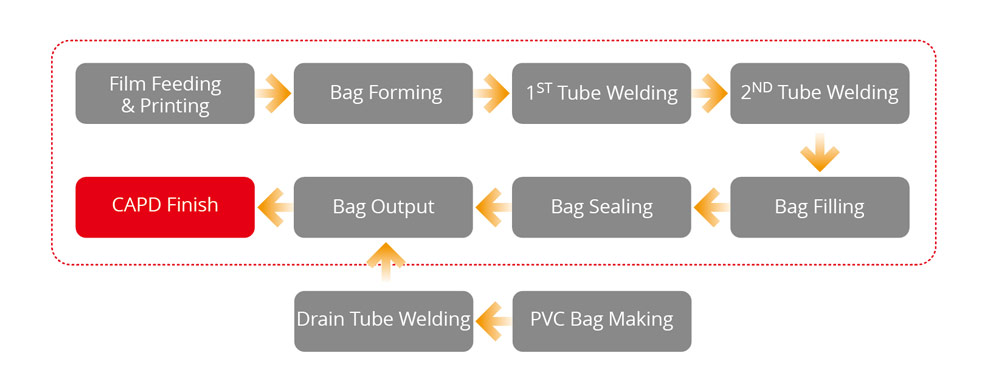

The production process of this peritoneal dialysis solution bag manufacturing line involves several key stages to ensure precision, efficiency, and compliance with stringent quality standards.

● Film Feeding & Printing:

The process initiates with the precise feeding of medical-grade films into the system. Advanced printing technology applies essential product information. This phase ensures accurate material alignment and labeling to meet regulatory requirements.

● Bag Forming:

The film undergoes meticulous forming, where it is shaped into the specified bag structure. This stage emphasizes precision in creating the appropriate dimensions and configurations required for peritoneal dialysis solution containment.

● Tube Welding:

Following bag formation, the system integrates tubing with exacting precision. High-frequency welding technology secures the tubing, ensuring a robust and leak-proof connection. This step is critical to maintaining the integrity of the entire fluid delivery system.

● Bag Filling:

The sterile peritoneal dialysis solution is precisely measured and introduced into the formed bags. The filling process is automated and closely monitored to guarantee accuracy, consistency, and adherence to specified volume requirements. This stage prioritizes aseptic techniques to prevent contamination.

● Bag Sealing:

Once filled, the bags undergo a meticulous sealing process. Advanced heat-sealing technology is employed to securely seal the bags, maintaining the sterility and integrity of the dialysis solution within. This step is crucial for ensuring the safety and efficacy of the final product.

● Bag Output:

Subsequently, the sealed bags are systematically removed from the production line. This step involves careful handling to prevent any compromise to the sterile environment. Quality checks are conducted to verify the completeness of the bags before they move on for packaging and distribution.

This comprehensive production process underscores the commitment to delivering high-quality peritoneal dialysis solution bags that meet the stringent standards of the healthcare industry, ensuring patient safety and product reliability.

-

● Efficient Production: Utilizes advanced technology for high-yield peritoneal dialysis solution bag filling, optimizing overall production efficiency.

-

● Automated Control: Equipped with state-of-the-art automated control systems, ensuring fully automated production, reducing manual intervention, and enhancing consistency and product quality.

-

● Flexible Adaptability: Adjusts production parameters to accommodate various specifications and requirements, enhancing the production line's versatility.

-

● Stringent Quality Control: Implements rigorous quality control standards and detection systems at every production stage, ensuring compliance with medical device quality requirements.

-

● Energy-efficient and Environmentally Friendly: Designed with energy-efficient features, employing advanced manufacturing processes to minimize resource consumption and waste generation.

-

● User-Friendly Operation: Features an intuitive and user-friendly interface, simplifying operation and reducing training costs for personnel, ultimately boosting production efficiency.

-

● Reliable Stability: Utilizes high-quality materials and components, subjected to rigorous testing to guarantee the reliability and stability of the production line.

-

● Compliance with Standards and Regulations: Adheres to relevant medical device production standards and regulations, ensuring that the produced peritoneal dialysis solution bags meet regulatory requirements.