language

BFS (Blow-Fill-Seal) Solutions for Intravenous (IV) and Ampoule Products

BFS for Intravenous (IV) and Ampoule is a new and innovative device that helps to improve the efficiency and accuracy of manufacturing intravenous (IV) and ampoule products. BFS for Intravenous (IV) and Ampoule is a valuable tool for pharmaceutical manufacturers who want to improve the quality, efficiency, and accuracy of their manufacturing processes. The BFS system can help manufacturers to save time and money, and to improve the quality of their products.

Email: iven@pharmatechcn.com

Tel: +86 21 58716151

Introduction

BFS for Intravenous (IV) and Ampoule is a new and innovative device that helps to improve the efficiency and accuracy of manufacturing intravenous (IV) and ampoule products. BFS for Intravenous (IV) and Ampoule is a valuable tool for pharmaceutical manufacturers who want to improve the quality, efficiency, and accuracy of their manufacturing processes. The BFS system can help manufacturers to save time and money, and to improve the quality of their products.

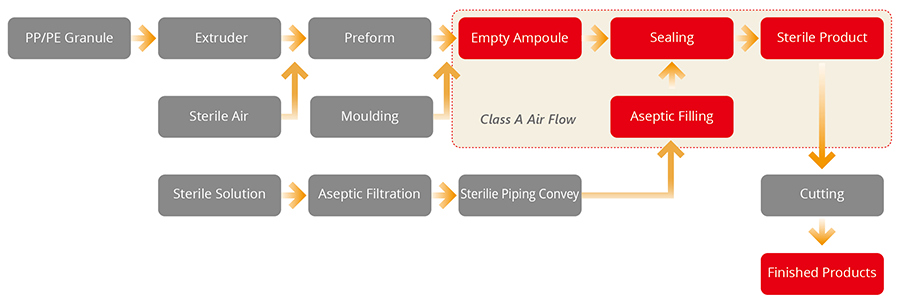

Blow-Fill-Seal production line adopts specialized aseptic packaging technology. It can work continuously and blow the PE or PP granules to container, then finish filling and sealing automatically and produce the container in a quick and continuous way. It combines several manufacturing processes in one machine, which can finish blowing-filling-sealing processes in one working station under the aseptic condition, to make sure the safety in use.

It can be widely used in the terminal sterilization products and aseptic products such as large volume IV bottles, small volume injectable ampoules or eye drops etc. This blow-fill-seal technology has the features of sterility, no particles, no pyrogen, and recommended by USA Pharmacopeia.