language

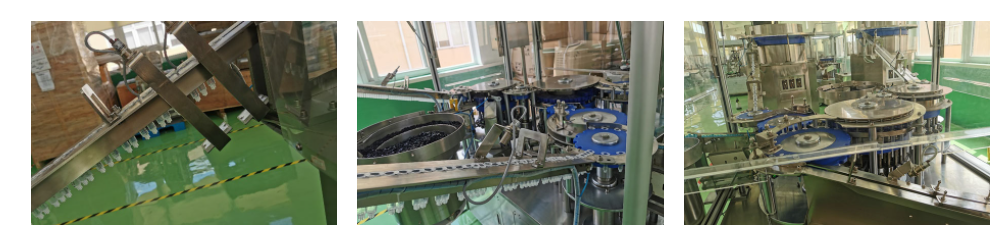

Syringe Assembling Machine

Our Syringe Assembling Machine is used for assembling syringe automatically. It can produce all kinds of syringes, including luer slip type, luer lock type, etc.

Our Syringe Assembling Machine adopts LCD display to display the feeding speed, and can adjust the assembly speed separately, with electronic counting. High efficiency, low power consumption, easy maintenance, stable operation, low noise, suitable for the GMP workshop.

Product Description

Our syringe assembling machine consists of feeding system and assembly mechanism.

Feeding system: feed 4 components of syringe (plunger/stopper/needle/barrel) to the assembly mechanism.

Feeding system are composed of feed bin and centrifugal feeder for barrel/plunger, hopper and feeder for needle/stopper.

Feeding system with photoelectric sensors, when assembling mechanism is full of products it will stop feeding, and when there is lack of products it will start working automatically.

Assembly Mechanism: assemble all parts of components together as a finished product. Usually, It completes 3 actions: action 1 – assemble plunger with rubber stopper; action 2 – assemble barrel with needle; action 3 – assemble plunger with stopper and barrel with needle.

Features

Increased Efficiency and Productivity: Machines operate around the clock with minimal breaks, significantly boosting production volume compared to manual labor.

Enhanced Sterility: Automated processes minimize human intervention, reducing the risk of contamination in the sterile environment.

Improved Consistency: Machines perform tasks with precise repetition, leading to consistent quality and reduced human error.

Reduced Labor Costs: Automated line require fewer personnel, optimizing production costs.