language

Mini Vacuum Blood Collection Tube Assembly Production Line

- Applicable Tube Size Φ13*75/100mm; Φ16*100mm

- Working Speed 10000-15000pcs/hour

Email: iven@pharmatechcn.com

Tel: +86 21 58716151

Introduction

The production line adopts highly integrated modular design, which integrates the core processes of tube loading, liquid addition, drying and vacuuming into independent units, with the volume of each module only 1/3-1/2 of the traditional equipment, and the overall length of the line reaches 2.6 meters (the traditional line length reaches 15-20 meters), which is suitable for the layout of narrow space. The blood collection tube mini assembly line includes stations for loading blood collection tubes, dosing reagents, drying, sealing and capping, vacuuming, and loading trays. With PLC and HMI control, the operation is simple and safe, and only 1-2 workers are needed to run the whole line well. Compared with other manufacturers, our equipment is characterized by compactness and space-saving features, including smaller overall size, higher automation and stability, and lower failure rate and maintenance cost.

Product Video

Application

For vacuum or non-vacuum blood collection tube production.

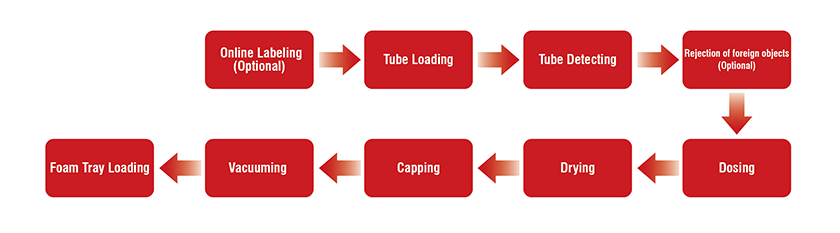

Production Procedures

Tube Loading & Detection

Automatic tube loading technology, loading the tube into clamps automatically with detector for no tube or inverse direction tube. The machine apply for any kind of label tubes and solve the defect of the avo label broken of traditional tube loading machine from other manufacturers.

Chemical Dosing

Equip with 3 dosing system, according to customer blood collection tube production demand.

USA FMI pump, spray dosing

Syringe pump lifting dosing

Syringe pump filling dosing

Drying System

The machine has function of automatic cap arranging, cap feeding, cap in place detection, capping detection. Inside of the tube will automatically produce a certain negative pressure, then automatically load tube into the tray.

Capping & Vaccuming & Tray Loading

There are 4 sets drying system, adopt PTC heating, no pollution to the inside of tubes, and achieve high efficiency of drying. It has correct positioning device for the hot rods and tubes.

IVEN Mini Blood Collection Tube Production Line Advantages

- 1. Compact and flexible dimensions, greatly improving the utilization of space.

2. High degree of automation, reasonable operation flow, integrated optimization, 1-2 skilled operators can smoothly manage the whole production line from tube loading to finished product output.

3. Multi-directional inspection, such as tube return, missing tube, dosing, drying temperature, cap seating, foam tray loading, etc., with high qualified rate of vacuuming.

4. Unique spring-type tube rack design allows easy operation and accurate vacuum setting on the touch screen, and the corresponding vacuum value can be set automatically according to the altitude of the user's region.

Machine Configuration

Tech Parameters

Excellent Customer